Professional team with materials science background

Failure Analysis of Metallic Materials

Due to the harsh working environment, special alloy components with high material cost and production difficulty are often used in the core components of industrial processes or equipments. When these components fail during the manufacturing process, the impact is extensive.

In addition to the cost of replacing new components, it is even worse to stop the production process for maintenance. Therefore, a comprehensive material failure analysis of anomalous alloy components is a crucial part of ensuring future process stability.

TCA has maintained a close cooperative relationship with customers for a long time, and has often assisted customers to select more proper materials for components with short life and poor performance in the process.

These successful cases are based on the accurate failure analysis, and we firmly believe that the premise of solving the problem is to thoroughly understand the problem.

Clarify the working environment

First of all, the working environment of the components must be confirmed. According to the environmental features, it can be preliminarily judged whether the failure of the components is caused by the wrong material selection or not. If the material is selected correctly, there may be unpredictable abnormalities occurring in the working environment.

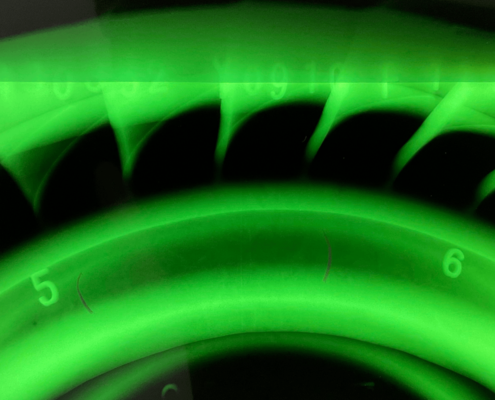

Non-destructive tests

Through non-destructive tests, we can identify the surface and internal quality of damaged components, generally using X-ray inspection and liquid penetration inspection. The purpose is to confirm whether the failure of the component is caused by unacceptable manufacturing quality or not.

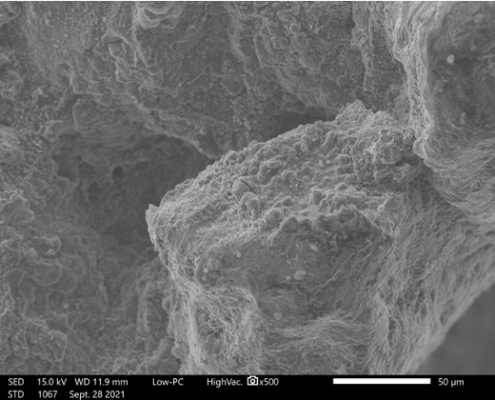

Material characterizations

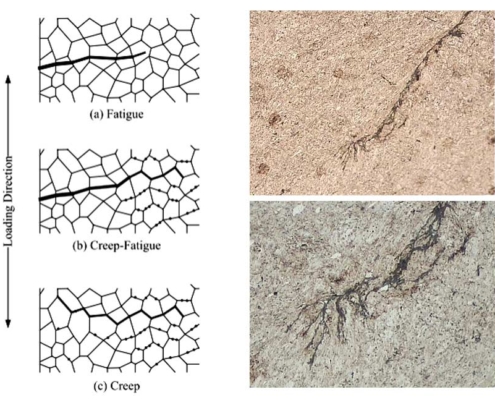

The core of failure analysis lies in the detection of material properties. According to the damaged material properties, we can clearly know what environmental conditions the parts have endured during use. For example, through microscopic metallographic analysis of material fractures, it is possible to understand the starting point of cracking and whether it is brittle or ductile fracture.

Failure mechanism

Combining the material testing results and the theoretical basis of materials science, we can analyze the cause of the failure and its mechanism.

Propose improvement plans and produce improved products

Based on the failure analysis results, we will suggest different improvement solutions to solve the problem from the perspective of cost and performance. In many cases, improvements can be made by adjusting mechanical design or upgrading materials. After the improvement plan is decided, the process will enter the pilot production stage. After the customer approves the performance of the new product, it will be put into mass production.