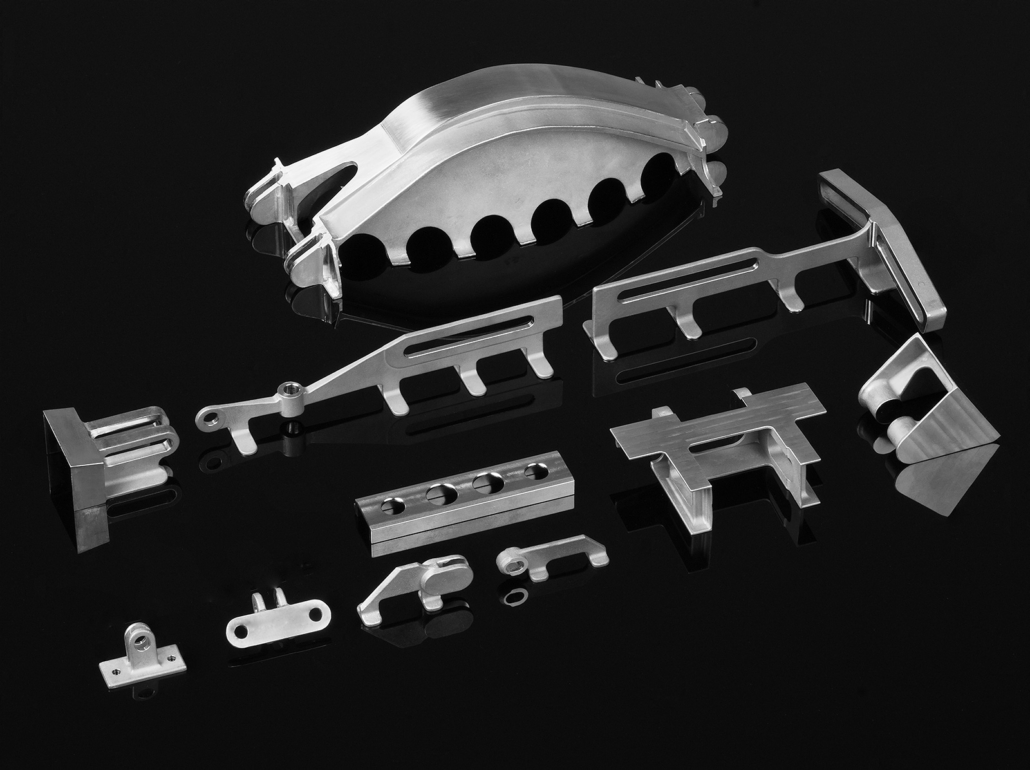

Investment Cast Products

In the production of investment castings, the ceramic shell mold is first created with a wax master mold, then dewaxed by high-pressure steam and sintered in high temperature furnace, and then the metal pouring is completed in a vacuum system, and finally the key dimensions of castings will be precisely machined.

Fine surface roughness of the casting (Ra2.5)

Precise dimensional tolerance

Various alloys are available:

- Iron-based alloys (stainless steel, high-alloy cast iron, heat-resistant steel, duplex stainless steel…etc.)

- Nickel-based alloys (Inconel®, Monel®, Incoloy®, Hastelloy®… and other alloys)

- Cobalt-based alloys (Stellite®, HAYNES® series alloys)

- Customized alloy

Features

The melting process of nickel-based and cobalt-based superalloy materials is carried out in a vacuum environment. Not only can the cleanliness of molten metal and product quality be greatly improved, but it also provides a more comprehensive guarantee for the safety of operators and environmental protection.

The maximum size of the casting is about 500mm in diameter, and the maximum weight is about 100kg.

Applications

We provide various kinds of products, and the applicable industries include petrochemical, energy, pharmaceutical…etc. Suitable material selection can be made according to the working environment, and there are corresponding solutions for extremely severe environments such as strong acid, strong alkali, high loading in high-temperature environment, high-temperature corrosion, high-temperature wear and even more complex environments.

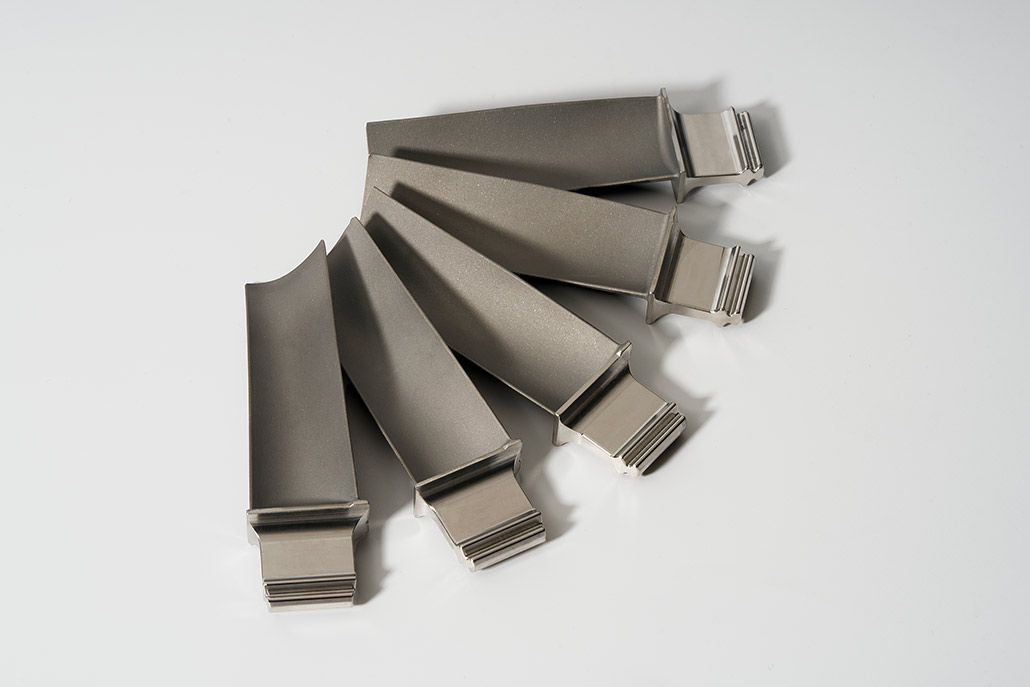

Special alloy bushing

Material:Hastelloy® C、Monel®、Carpenter®-20Cb

Material: Cobalt-based alloys, Nickel-based alloys, stainless steel

Material: Nickel-based superalloy

Production method: Vacuum Investment Casting

Quality: AMS 2175 Class 1 Grade C

Material: Nickel-based superalloy

Production method: vacuum casting

Quality: AMS 2175 Class 1 Grade B & C

Material: Cobalt-based superalloy (Stellite® No.31, No.25, X-45)

Material: Nickel-based Superalloy

Production method: Vacuum Investment Casting

Quality: AMS 2175 Class 1 Grade B