Innovation and Cooperation

TCA has always been committed to the frontier research of materials science and has cooperated with top universities and institutes.

Our ultimate goal is to apply innovative materials science research to the practical use, and to support industry-academy cooperation while enhancing the competitiveness of metal industry in Taiwan.

Research Achievements

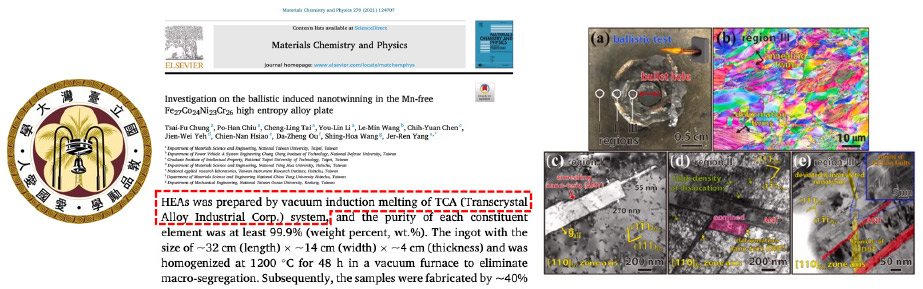

National Taiwan University – High-entropy Alloys

TCA cooperated with the department of materials science and engineering of National Taiwan University to develop a manganese-free quaternary FeCoNiCr high-entropy alloy. Within the resaerch, the alloy was deformed at room temperature with an extremely fast strain rate (>10^6 s^-1). Nanotwins are found to nucleate at the stacking faults to accommodate instantaneous local deformation. The target application of this material is bulletproof steel plate.

TCA is responsible for the manufacturing of the alloy, and National Taiwan University is responsible for alloy design, experimental research and paper writing.

Chung, Tsai-Fu, et al., Materials Chemistry and Physics 270 (2021): 124707.

https://doi.org/10.1016/j.matchemphys.2021.124707

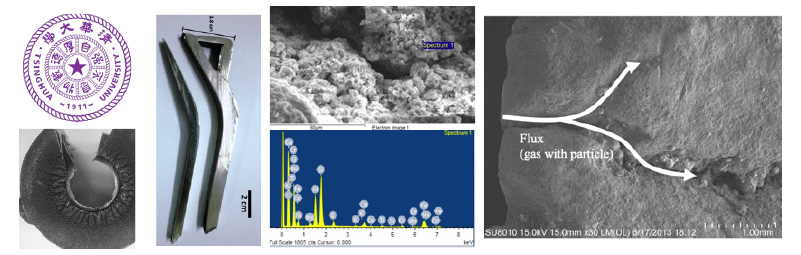

National Tsinghua University – High-entropy Superalloys

TCA cooperated with the department of materials science and engineering of National Tsinghua University to develop high-entropy superalloys. The concept is to introduce L12-gamma prime precipitation into the high-entropy matrix phase, which possesses extremely high solid solution strengthening effects. The goal is to surpass the high-temperature mechanical properties of traditional nickel-based superalloys so as to improve the thermal efficiency of turbine engines and reduce the use of fossil fuels.

TCA is responsible for manufacturing of alloy, and National Tsinghua University is responsible for alloy design, research experiments and research reports writing.

National Tsinghua University – Hot Corrosion of Co-based Alloys

TCA cooperated with department of materials science and engineering of National Tsinghua University to improve the material of a commercial Co-based alloy and manufactured a product for end-use testing. The results showed that the modified alloy effectively increased the service life.

TCA is responsible for alloy design, manufacturing process development, and National Tsinghua University is responsible for failure analysis, research experiments and research reports writing.